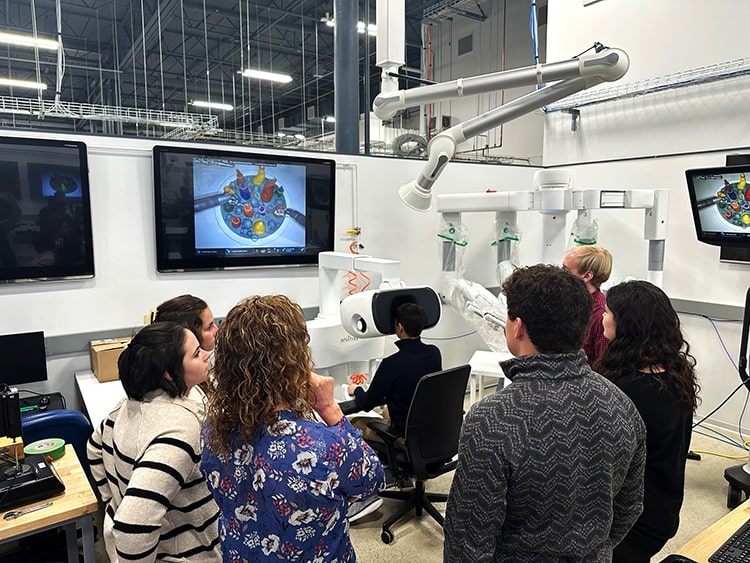

For 20 biomedical engineering students, a spring semester visit to Intuitive Surgical in Orange, Conn., wasn’t just a tour — it was a hands-on encounter with the future of robotic surgery.

Engineers at Intuitive Surgical, a global leader in robotic-assisted surgery, have spent nearly three decades refining technology to reshape how complex surgical procedures are performed. In early February, a group of biomedical engineering students were invited to experience the company's innovations first-hand as part of the School of Engineering and Computing’s Industry Day series.

For Maeve O’Connell ‘25, the highlight was getting to try out the Da Vinci 5, Intuitive’s newest multiport robotic surgery system. “It was so impressive,” she said. “The most surprising part of the tour was their machine shop. It was amazing to see how detailed all of the parts they create are, the plethora of advanced machines they have, and how much work goes into such small, but meaningful parts.”

Used in a wide range of procedures — from hernia repairs to lung surgeries — the Da Vinci system allows surgeons to operate with precision using robotic arms equipped with specialized tools like graspers, scalpels, and electrocautery instruments. O’Connell and her classmates had the opportunity to sit at the console and attempt delicate tasks using the device. “It was surprisingly so much easier to use than I had expected,” she said. “The precision of the device is what amazed me the most. Any tremors generated by our hands were eliminated through the device’s noise-dampening algorithms, so the robot’s movements were far smoother and more accurate than what the average human can do.”

For Matthew Manduca '25, learning about the technology behind the Da Vinci 5 was the most exciting part of the visit. “The device itself is innovative, providing a truly immersive robotic surgery experience, and the technology behind it was incredible to learn about,” he said. Manduca was particularly fascinated by how the device’s arms mimic the movement of a surgeon’s wrists, providing an extra range of motion. “There is a learning curve, but the device was a lot more intuitive than I thought it would be,” he noted. Using it to unwrap a small candy, he discovered that even such a simple task became an exercise in precision and control.